Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Back sealing Liquid/sauce packing machine

Back sealing liquid/sauce packing machines, including the JK-320LB, JK-380LB, and JK-480LB models, offer versatile solutions for packaging liquids efficiently. They accommodate a range of bag sizes and packing speeds to meet diverse production needs. With measuring ranges from 10ml to 1000ml and powered by a 2KW, 220V, 50Hz system, these machines ensure precise measuring.

Back Sealing Liquid/Sauce Packing Machine

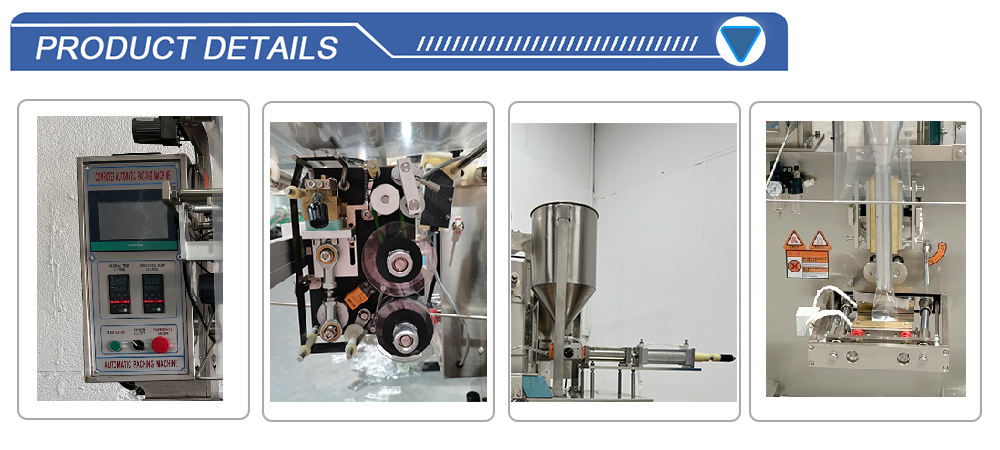

Product Description

The back sealing liquid/sauce packing machines, such as the JK-320LB, JK-380LB, and JK-480LB models, are designed for efficient packaging of liquids. They offer flexibility with adjustable bag sizes and packing speeds to cater to various production demands. Featuring measuring ranges from 10ml to 1000ml and powered by a 2KW, 220V, 50Hz system, these machines ensure accurate measurement. Their compact designs, ranging from 950mm to 980mm in length, and weights from 310kg to 520kg, make them suitable for diverse liquid packaging applications in industries such as food.

Product Specification

| Model | JK-320LB | JK-380LB | JK-480LB |

| Bag Size(mm) | W:30-140 L:50-170 | W:50-200 L:100-250 | W:80-230 L:80-290 |

| Packing Speed | 20-60 bags/min | 15-40 bags/min | 10-30 bags/min |

| Measuring Range | 10-100ml | 100-300ml | 100-1000ml |

| Power | 2KW,220V,50HZ | 2KW,220V,50HZ | 2KW,220V,50HZ |

| Machine Size(L*W*H) | 950*1120*1770mm | 950*1120*2070mm | 980*2000*2150mm |

| Machine Weight | 310kg | 400kg | 520kg |

Product Features

Wide Measuring Range: Accurately measures liquid volumes from 10ml to 1000ml, catering to a variety of packaging needs with precision.

Efficient Power Usage: Runs on a 2KW, 220V, 50Hz system, balancing energy efficiency with consistent performance.

Compact Design: Features space-saving dimensions and weights (310kg to 520kg), ideal for optimizing floor space and seamless integration into production lines.

Compliance and Quality Assurance: Meets industry standards and regulatory requirements, ensuring safety, hygiene, and quality in liquid packaging processes.

Product Advantages

Incorporating Advanced Design and Materials for Enhanced Cleanliness in Liquid Packaging: Back sealing liquid/sauce packing machines prioritize hygiene through their design and materials. They often feature stainless steel construction for parts that come into contact with liquids, ensuring they are corrosion-resistant and easy to clean. Smooth surfaces and minimal crevices reduce the risk of bacterial growth and facilitate thorough sanitation between production runs.

Enhancing Product Viability and Market Penetration through High-Quality, Efficient Liquid Packaging Solutions: These machines enhance market competitiveness by consistently delivering high-quality liquid packaging solutions. They ensure precise measuring, secure sealing, and efficient production rates, meeting diverse market demands effectively. By optimizing packaging processes, they reduce costs associated with labor and material wastage, making products more competitively priced.